SHUTTLE KILNS

The shuttle kilns are versatile solutions with a range of options from furnaces of small capacity up to 140m³ – within our portfolio.

From several applications with this type of kilns, we point out: Heavy clay; porcelain, sanitaryware, earthenware, stoneware, refractory material, using temperatures up to 1800ºC.

Thanks to the type of insulation applied, particularly ceramic fibre, shuttle kilns are equipments of great flexibility, allowing short or long cycles, depending of the firing product.

The high technological level reached on conception and insulation, as well as the use of more refined burning and control systems, allows building shuttle kilns in any capacity.

Depending on its capacity and application, several types of doors can be installed, with manual or automatic motion, according to the needs of each client.

On shuttle kilns with higher capacity, we are able to apply semi-automatic or fully automatic systems of kilns cars motion (pull/push).

TABLEWARE

SANITARYWARE

TECHNICAL CERAMICS & REFRACTORIES

STRUCTURAL

TERRACOTTA

TUNNEL KILNS

ELECTRIC, GAS OR LIQUID FUEL

Tunnel kilns are normally designed for continuous production and more homogeneous loads, capable of faster firing cycles than shuttle kilns. These kilns are also more efficient, with significantly lower energy consumption than shuttle kilns, considering the same production capacity.

The development of our solutions is ensured by a project technical team with extensive experience and expertise based on real applications, in the several areas. Insulation, heating, control and regulation systems are studied to have a rigorous distribution along the kiln in order to meet the requisites of the requested firing curves.

From the several applications of this type of kiln we highlight: heavy clay; porcelain, sanitaryware, earthenware, stoneware, decoration, using temperatures up to 1.450ºC.

In smaller kilns, with temperatures up to 1.150ºC, conveyor belt (with metallic mesh) with electromechanical drive can be considered.

HEATING PROCESS

Made through heating elements, gas burners (high speed – JET) or liquid fuel, projected according to each kiln characteristics and firing type.

INSULATION

Ceramic fibre and other low thermal mass materials, very flexible considering the cycle time: faster or slower cycles, according to the firing needs.

The insulation with refractory and insulating bricks, as well as refractory concrete, are normally applied on the manufactured models, balancing the requisites of each firing and the impact of the thermal shock on the kilns cars on continuous motion.

AUTOMATIC MOTION

We offer several solutions of kiln cars automatic motion systems, by hydraulic or electro mechanical process.

TABLEWARE

SANITARYWARE

TECHNICAL CERAMICS & REFRACTORIES

STRUCTURAL

TERRACOTTA

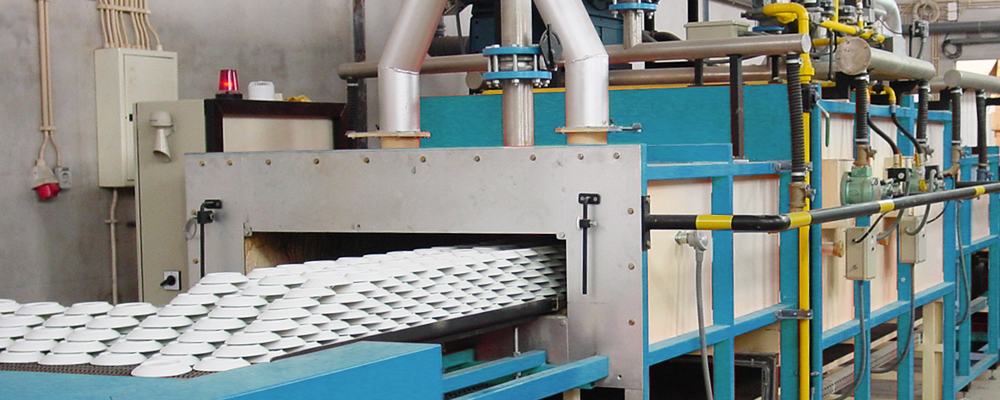

ROLLER KILNS

ELECTRIC OR GAS

Kilns for continuous production and more homogeneous loads, capable of faster firing cycles than shuttle kilns. These kilns are also more efficient, with significantly lower energy consumption than shuttle kilns, considering the same production capacity.

The development of our solutions is ensured by a project technical team with extensive experience and expertise based on real applications, in the several areas. Insulation, heating, control and regulation systems are studied to have a rigorous distribution along the kiln in order to meet the requisites of the requested firing curves.

From the several applications of this type of kiln we highlight: porcelain, earthenware, stoneware, decoration; with temperatures up to 1.300ºC.

HEATING PROCESS

Made through heating elements, gas burners (high speed – JET) or liquid fuel, projected according to each kiln characteristics and firing type.

INSULATION

Ceramic fibre and other low thermal mass materials, very flexible considering the cycle time: faster or slower cycles, according to the firing needs. The insulation with refractory and insulating bricks, as well as refractory concrete, are normally applied on the manufactured models, balancing the requisites of each firing and the impact of the thermal shock.

AUTOMATIC MOTION

Roll movement by electro mechanical process.

Possible integration with other automatic motion systems.

TABLEWARE

TERRACOTTA

ELEVATOR AND TOP HAT

ELECTRIC, GAS OR LIQUID FUEL

Periodic kilns without door, where the seal is made with the bottom kiln / kiln car.

• ELEVATOR – kiln is on a higher level and kiln car lifts/rises to seal with the kiln.

• TOP HAT – kiln car is on the floor/ground level and the kiln comes down to seal with the kiln car.

The lifting system may be electromechanical or hydraulic.

The biggest advantage of this type of kilns is an increased control of the atmosphere and pressure. These solutions are typically designed to meet the needs of each firing curve and product to fire.

From the several applications of this type of kiln we highlight: abrasives, technical ceramics, refractory material, with temperatures up to 1.800ºC.

Possible integration with other automatic motion systems.

TECHNICAL CERAMICS & REFRACTORIES

ABRASIVES

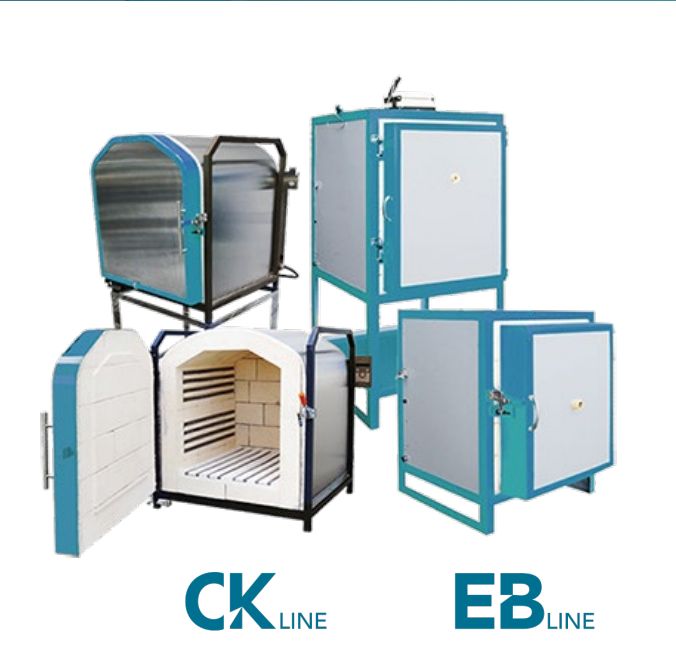

CRAFTS AND LABORATORIES KILNS

CK & EB Line

Solutions for ceramists, art studios, professionals and laboratories, for occasional, regular or intensive use.

CK kilns are an excellent choice for any application, distinguished by:

- High rate of rise capability, 20°C to 1320°C in 6 hours (with load);

- Adjustable air inlet for faster cooling;

- Rear chimney for efficient exhaust and cooling;

- Ventilated door;

- BentrupTC88e digital controller, easy to use with high temperature accuracy – PID system.

The EB ovens specific design, excellent insulation and power rating, result in:

- Low energy consumption in relation to the firing power;

- Very fast firing cycles if required;

- Uniform temperature distribution throughout the entire firing load;

- Very low thermal mass;

- BentrupTC88e digital controller, easy to use with high temperature accuracy – PID system.

TECHNICAL CERAMICS & REFRACTORIES

TABLEWARE

TERRACOTTA

NEED MORE TECHNICAL INFORMATION?

Would you like to receive more technical information by e-mail?

Please tell us more about you and your project.