EB LINE

EB LINE

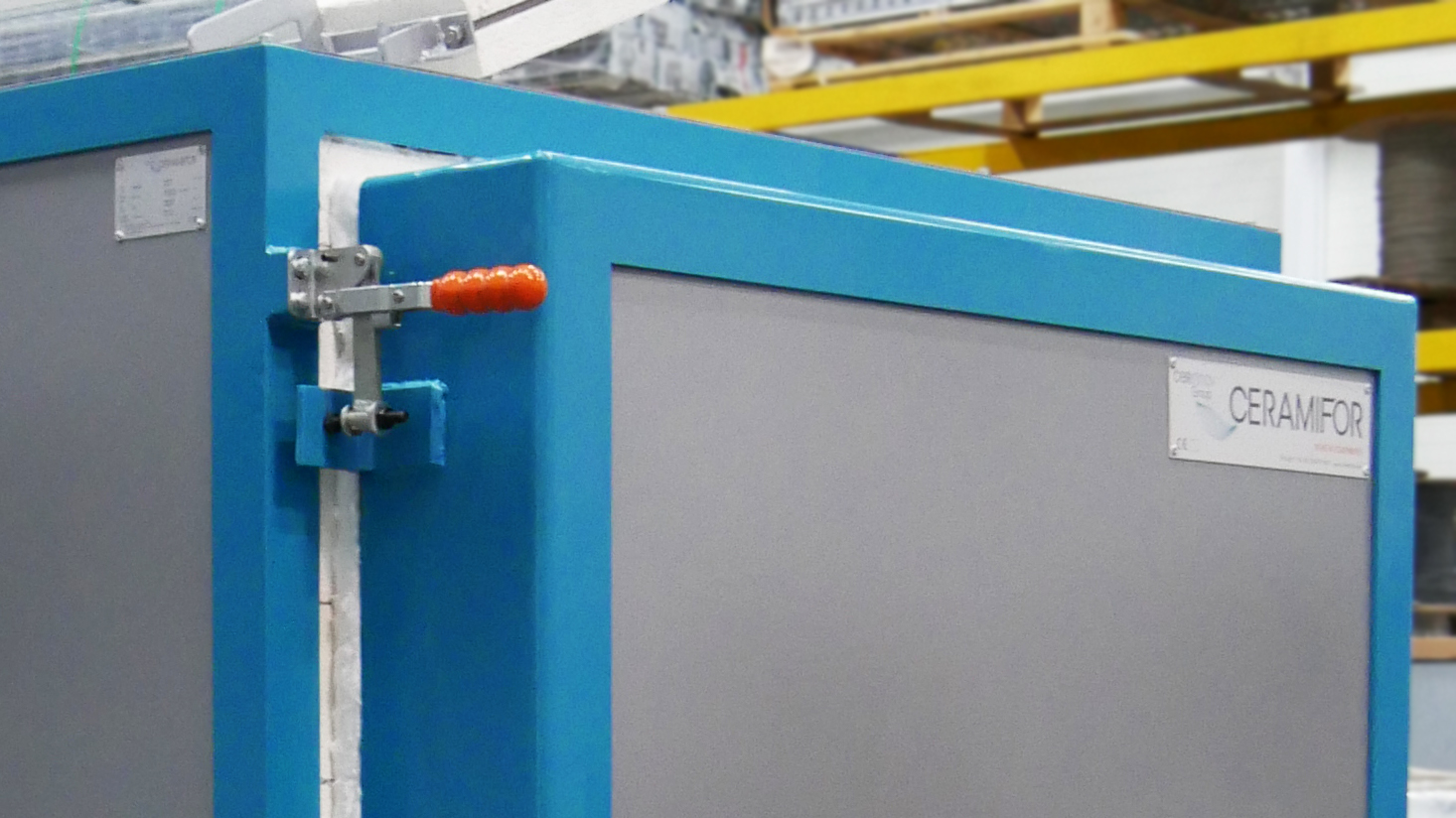

CERAMIFOR also has solutions adapted to ceramists, art studios, professionals and laboratories, for occasional, regular or intensive use.

The specific design of EB kilns, excellent insulation and power rating, results in:

- Low energy consumption in relation to the firing capacity;

- Very fast firing cycles when necessary;

- Uniform temperature distribution throughout the firing load;

- Very low thermal mass;

- Digital controller BentrupTC88e, easy to use with high temperature precision – PID system.

Maximum temperature

1300 °C

Kiln construction

Mild steel casing with steel sheets

2.5 mm thick

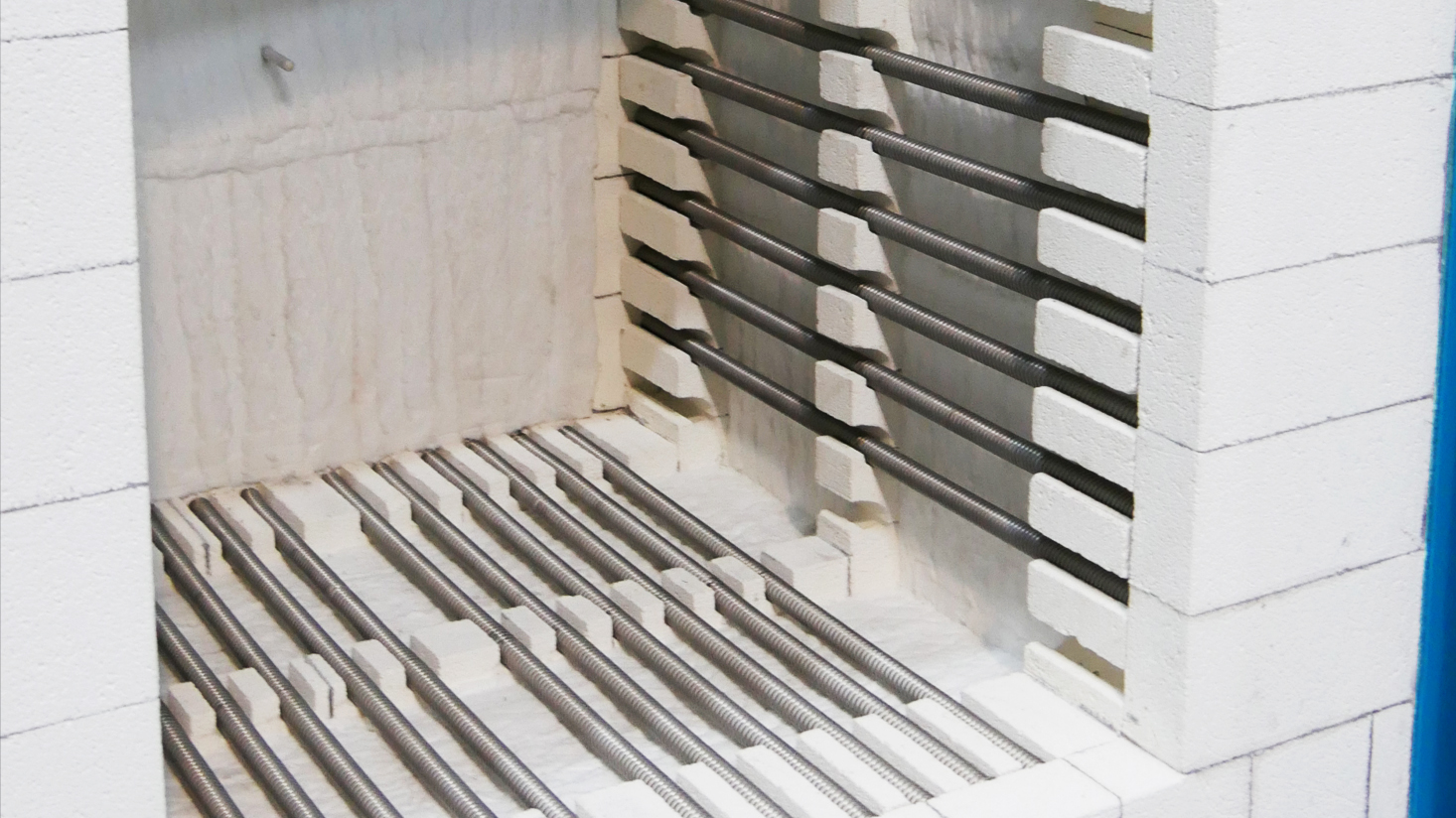

Heating system

Kanthal A1 / Resustohm 145 heating elements supported by high alumina ceramic tubes

Temperature controller

Digital controller Bentrup TC88e

Insulation

High alumina insulating bricks combined with ceramic fiber

MEC 85

- Internal volume (L): 85

- Internal dim. W x D x H (mm): 380 x 600 x 420

- External dim. W x D x H (mm): 760 x 1230 x 1480

- Weight: 450 Kg

- Power: 7.5 kW

- Current (A): 11/Phase

- Voltage (V) : 3 x 400+N

EB 220

- Internal volume (L): 220

- Internal dim. W x D x H (mm): 500 x 765 x 650

- External dim. W x D x H (mm): 1070 x 1270 x 2070

- Weight: 910 Kg

- Power: 21 kW

- Current (A): 32/Phase

- Voltage (V) : 3 x 400+N

EB 160

- Internal volume (L): 160

- Internal dim. W x D x H (mm): 460 x 645 x 650

- External dim. W x D x H (mm): 990 x 1170 x 2040

- Weight: 702 Kg

- Power: 21 kW

- Current (A): 32/Phase

- Voltage (V) : 3 x 400+N

EB 500

- Internal volume (L): 502

- Internal dim. W x D x H (mm): 610 x 730 x 930

- External dim. W x D x H (mm): 1190 x 1400 x 2170

- Weight: 1200 Kg

- Power: 35 kW

- Current (A): 46/Phase

- Voltage (V) : 3 x 400+N

NEED MORE TECHNICAL INFORMATION?

You want to receive more technical information by e-mail?

Please tell us more about you and your project.

Please tell us more about you and your project.